Ionic liquids open door to better rare-earth materials processing

U.S. Division of Energy's Ames Laboratory and Essential Materials Institute components chemist Anja Mudring is harnessing the promising qualities of ionic liquids, salts in a liquid state, to optimize processes for vital components. "ionic liquids have...

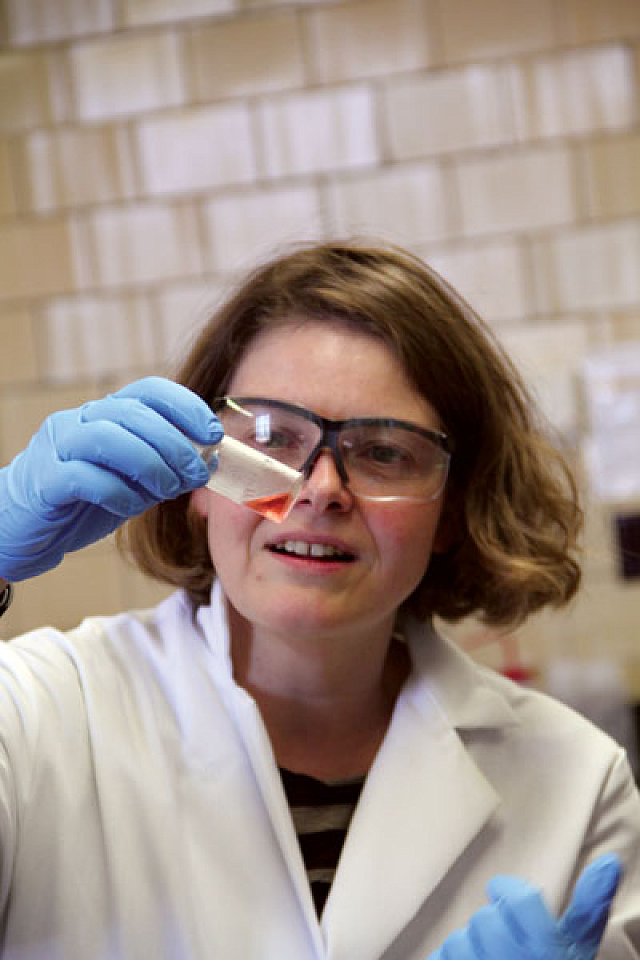

U.S. Division of Energy's Ames Laboratory and Essential Materials Institute components chemist Anja Mudring is harnessing the promising qualities of ionic liquids, salts in a liquid state, to optimize processes for vital components.

"Ionic liquids have a lot of valuable qualities, but most valuable for materials processing is that ionic liquids are created up of two components: the cation and the anion. We can play around with the chemical identities of every single of those components and that opens the doors to big amount of possibilities," says Mudring. "That indicates we can genuinely engineer ionic liquids with distinct functions in mind."

1 such function is enhancing the uncommon-earth separation course of action, either for extracting rare earths from ore or recycling rare earths from discarded magnets.

"We are tuning the ionic liquids in such a way that they dissolve uncommon-earth oxides and then we're utilizing electrodeposition, where electrical energy is run through a liquid to produce a chemical alter to get the rare earth in metal form," says Mudring, who is also a professor of materials science and engineering at Iowa State University.

Traditionally, electrodeposition processes are very high temperature and generally demand corrosive chemical substances. But Mudring's process calls for substantially lower temperatures and ionic liquids are less hazardous, so significantly less energy is necessary and the method is safer and greener.

Mudring's group is also employing ionic liquids to produce phosphors for compact fluorescent light bulbs.

"We're employing ionic liquids, placing them in a microwave, energizing them, and making a phosphors material. The phosphors particles are much less than 10 nanometers, which means they do not scatter light, crucial for optical applications like for compact fluorescent light bulbs," says Mudring.

Far better however, Mudring's method also reduces the quantity of rare-earth supplies required in the method, and could someday make it achievable to replace mercury vapor with significantly less-hazardous noble gases in CFLs. And hunting farther down the road, the new phosphors could also be utilised in LEDs as they continue to replace CFLs.

"Ionic liquids are the essential to the improvements in this material synthesis," says Mudring. "They function as the solvent, a safer 1 than an alcohol or other combustible solvent. And they are also the reaction companion: Right here, the ionic liquid is the fluoride source, so we can omit hazardous hydrofluoric acid from the procedure. Again, that makes the procedure safer and cleaner. And they even function to stabilize the nanoparticles created in the approach, eliminating the need for an extra stabilizer. 3 functions in one particular! Add to that how effectively ionic liquids take up microwave energy and there is just enormous possible there for improving materials synthesis."

Our editors found this article on this site using Google and regenerated it for our readers.