Your Current Location is:Home > Application

Eastman Chemical Company's Isomerisation process based on ionic liquid

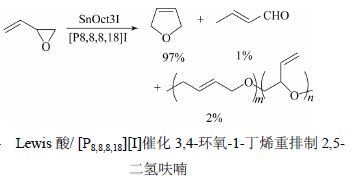

Although the BASIL TM process was the first publicly announced room-temperature ionic liquid process, and was launched with a significant amount of publicity, Eastman Chemical Company had been running a process for the isomerisation of 3,4-epoxybut-1-ene to 2,5-dihydrofuran since December 1996.

This was operated by the Texas Eastman Division, in a plant with a 1400 metric tons per year capacity, at Longview until the end of 2004. The epoxidation of butadiene to 3,4-epoxybut-1-ene had been discovered in 1986 by Dr John R. Monnier of the Eastman Kodak Research Laboratories, and its isomerisation to 2,5-dihydrofuran was later discovered in 1988 by Dr Stephen N. Falling and coworkers of the Eastman Chemical Company. This isomerisation process critically requires a Lewis acid catalyst, and a Lewis basic ionic liquid, [P888 18]I (ex Cytec). It operated with three continuous, stirred-tank reactors, a wiped-film evaporator, a distillation train, and a continuous, countercurrent, liquid–liquid extractor for recovery of the catalysts from December 1996 to December 2004. The phosphonium ionic liquid was selected over its ammonium analogue because of its greater thermal stability. The

plant is now idle, because the market for the product has declined.

1. Natalia V. Plechkova and Kenneth R. Seddon. Chem. Soc. Rev., 2008, 37, 123–150

2. S. N. Falling, J. R. Monnier, G. W. Phillips, J. S. Kanel and S. A. Godleski, First International Congress on ionic liquids (COIL-1), 19th–22nd June, Salzburg, Austria, 2005.

3. J. D. Holbrey, N. V. Plechkova and K. R. Seddon, Green Chem., 2006, 8, 411–414.

4. J. R. Monnier and P. J. Muehlbauer, Selective monoepoxidation of olefins, US Pat., 4,897,498 (1990).

5. G. W. Phillips, S. N. Falling, S. A. Godleski and J. R. Monnier, Continuous process for the manufacture of 2,5-dihydrofurans from c,d-epoxybutenes, US Pat., 5,315,019 (1994);

6. S. N. Falling, S. A. Godleski and L. McGarry, Process for the separation of oligomeric materials from a catalyst mixture, US Pat., 5,238,889 (1993).

-

Research Institute

-

Application Area

-

Ionic Liquids Used

Next Article:Eli Lilly’s demethylating process based on ionic liquid